When it comes to protecting sensitive electronics or building control systems, one question always comes up: Should I go with a custom enclosure or a standard one? The answer depends on your application, timeline, and budget.

At NEMA Supply, we offer both options—off-the-shelf enclosures ready to ship today, and fully customized solutions tailored to your exact needs.

🧩 When a Standard Enclosure Works Best

Standard enclosures come in a wide variety of sizes, materials, and ratings. Many users find that with the right accessories—like gland plates, knockout kits, or DIN rails—a stock enclosure can do everything they need.

Best for:

-

General electrical or control applications

-

Quick turnarounds

-

Budget-sensitive projects

-

Low-volume or one-off installs

Our standard options include polycarbonate, fiberglass, stainless steel, and more—with NEMA 4X, 6P, and 12 ratings available.

✏️ When to Go Custom

Sometimes your project calls for something specific—an unusual mounting layout, specialized ports, internal framing, or company branding. That’s where a custom enclosure pays off.

Best for:

-

High-volume OEM applications

-

Unique size or layout requirements

-

Branded equipment panels

-

Specialized thermal or EMC conditions

We work with leading manufacturers to provide cutouts, silk-screened logos, pre-installed components, and precision-fit designs.

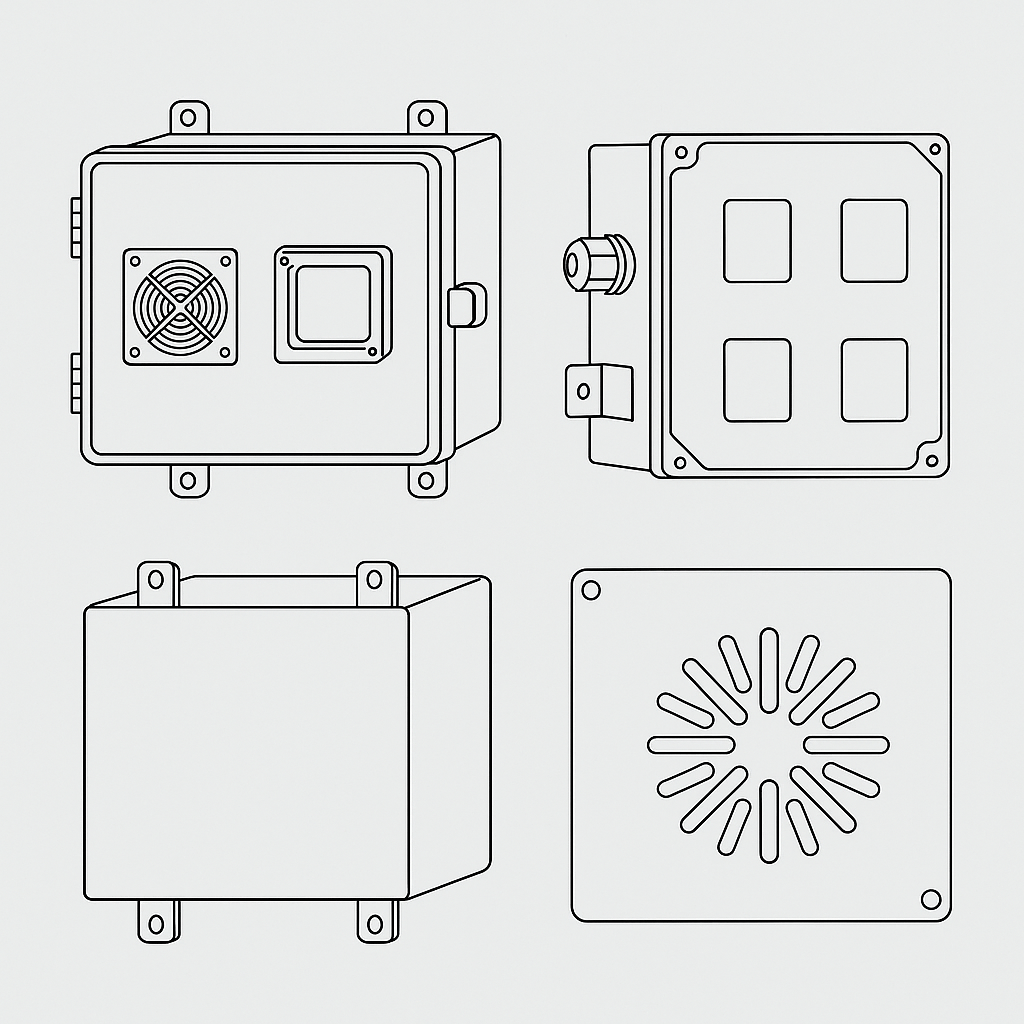

🛠️ Customization Options

-

CNC or laser-cut openings

-

Ventilation and thermal management

-

Mounting brackets and back panels

-

Pre-wiring and terminal block installation

-

Labeling and color options

📌 Final Thoughts

If your job demands speed and flexibility, start with a standard enclosure and modify it as needed. For higher-volume builds or complex specs, a custom enclosure can save time and cost in the long run.

Need help deciding? Our experts can guide you through the process.